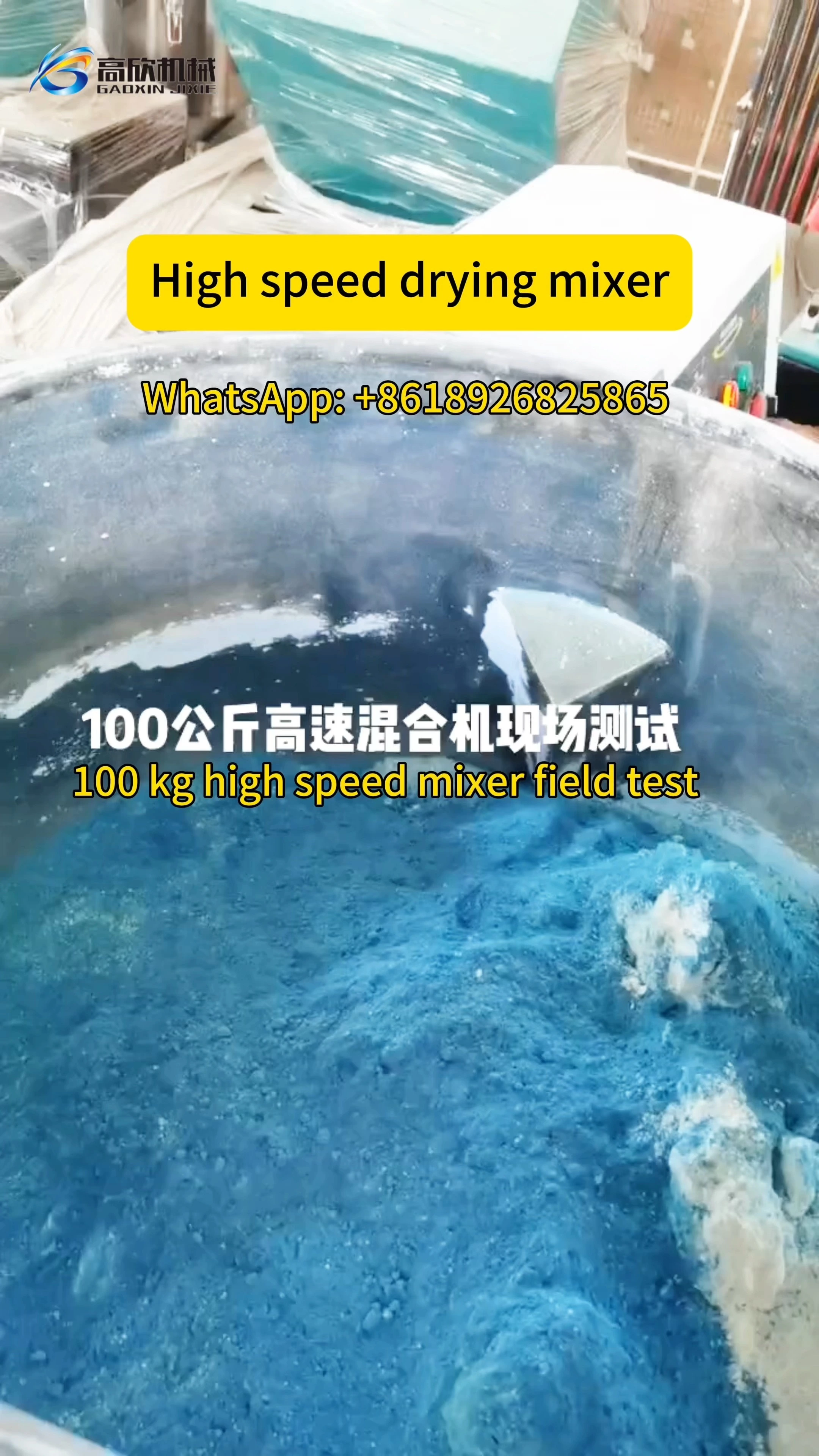

High-speed drying mixer, plastic quickly mix and mix, heat and dry, two-in-one function, 50kg-200kg model

Suitable for mixing various granular materials, crushed materials, and powder materials, with water removal and drying functions

Widely used in plastic raw materials, crushed materials, powder materials, chemical industry, food and other industries

Working principle of high speed drying mixer

The high-speed drying and color mixing machine uses the vortex-type high-speed operation of the drawing blade to make the plastic particles (or powder) tumble, collide, and friction at high speed to generate heat.

The material is mixed in color and the water is quickly evaporated from the exhaust pipe to achieve the purpose of drying. The effect is ideal.

High speed drying mixer features:

1.Has automatic functions such as automatic temperature control and timer overload protection;.

2.Double-layer stainless steel thermal insulation barrel, paddles, gate, barrel cover, etc. are all made of stainless steel.

3.The bottom of the barrel adopts a cone-shaped cornerless design and is matched with square paddles to make the raw materials rotate faster, the motor utilization rate is higher, and cleaning in the barrel is easier.

4.Easy to discharge materials, no need to start the motor.

Paddles inside the machine

Made of stainless steel, smooth and easy to clean, fast rotating speed, uniform mixing and fast heating.

Multiple models available

Suitable for mixing various granular materials, crushed materials, and powder materials, with water removal and drying functions

Widely used in plastic raw materials, crushed materials, powder materials, chemical industry, food and other industries

50KG---200KG optional

Machine details

Structural diagram of high-speed drying mixer

Automated use in injection molding, blow molding, granulation, food, and chemical industries

Technical parameters of high-speed drying mixer

| Model | Powre | Capacity | Voltage | Dimensions | Rotating speed | Net Weight |

| ZHVMG-50 | 7.5 KW | 50Kg | 380/ 3Φ | 1100*800*1300MM | 500/ Min | 230Kg |

| ZHVMG-100 | 15KW | 100Kg | 380 /3Φ | 1200*950*1400MM | 500/ Min | 550Kg |

| ZHVMG-200 | 30 KW | 200 Kg | 380 /3Φ | 1700*1300*1700MM | 480/ Min | 700Kg |

A corner of the high-speed drying and mixing workshop